The most common materials used in CNC machining custom machined parts

At our state-of-the-art facility, we cut precision machined parts out of a variety of materials, including aluminum, brass, stainless steel, steel, and plastics.

Our highly skilled team has the experience and expertise to work with even the most challenging specifications. In addition, we utilize the latest computer-aided design and manufacturing technology to ensure that every part meets the highest standards of quality. Whether you need a single prototype or a large production run, we are confident that we can exceed your expectations.

Aluminum

Aluminum is the most popular material in CNC machining, it is a lightweight metal with an excellent strength-to-weight ratio yet its durable nature makes it an optimal choice for a variety of applications across all industries.

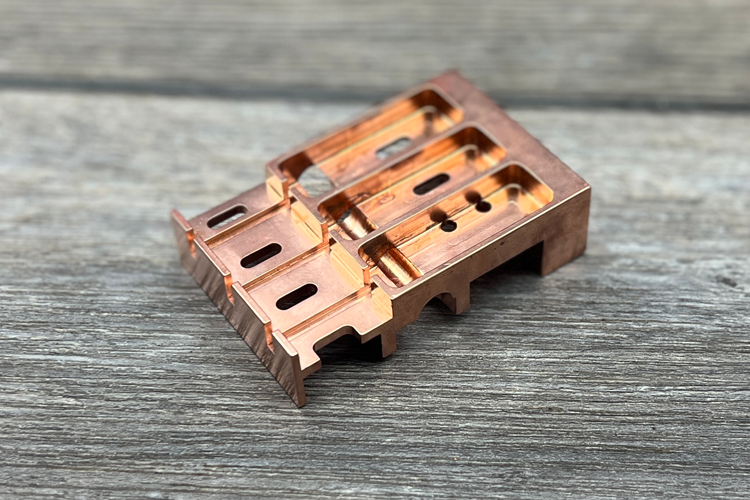

Brass

Brasses strength, machinability, and high corrosion resistance make it a go-to choice for outdoor use and marine applications. The alloy consists of both copper and zinc with a tensile strength like mild steel.

Stainless Steel

Stainless Steel is renowned for its corrosion resistance and machinability. Engineers favor its durability, perfect for intricate parts that have longevity in demanding applications.

Steel

Steel is known for its strength and versatility. Engineers harness its high carbon content for enhanced hardness, machining robust components with precision and high-level of performance.

Plastics

Machined plastic parts are typically utilized for their lightweight and malleability. Engineers leverage its low thermal conductivity for intricate designs, ensuring efficient cooling and precise machining in complex applications.