Manufacturing multi-part assemblies from precision machined components is a challenging process, requiring careful management of tight tolerances and tolerance stacking. Design modifications made to one part must be accounted for in all related components to ensure proper fit. Otherwise, misalignments and costly reworks may be required.

To overcome these challenges, it’s best to work with a single machine shop that can handle both the machining and assembly of all the parts involved. This ensures a precise fit and a finished assembly that’s within spec and functions as intended.

At Approved Machining, we offer CNC machining services and assembly all in one place. Our team of engineers and skilled machinists collaborate closely to maintain tight tolerances and manage tolerance stack-up, resulting in final products that meet and exceed your expectations.

But why is ensuring proper tolerance stack-up so difficult when working with multiple vendors? Let’s dig in.

Table of Contents

The Challenges of Using Multiple Shops for CNC Machined Assemblies

Manufacturing CNC machined assemblies becomes significantly more complicated if you work with multiple machine shops. This is especially true if you’re bringing a new product to market—design changes are inevitable, and you’ll need to maintain tolerance stack-ups across subassemblies and within the final product.

Manufacturing CNC machined assemblies becomes significantly more complicated if you work with multiple machine shops. This is especially true if you’re bringing a new product to market—design changes are inevitable, and you’ll need to maintain tolerance stack-ups across subassemblies and within the final product.

Coordinating across multiple machine shops is time-consuming — reason enough to work with a single manufacturing partner — and variations in quality and deviations from specified values can result in parts that don’t fit together correctly. If one machine shop needs to adjust a design for manufacturability, even slightly, you’ll need to contact other machine shops, potentially modifying more parts to ensure proper assembly.

However, if you work with a single precision machine shop to manufacture all of your parts and assemble your finished product, you simplify communication by having just one manufacturer oversee the entire process. At Approved Machining, when design modification is required for one part, we can ensure that any modifications that need to be made to other parts are implemented accurately and efficiently. This streamlines your entire manufacturing and assembly process, creating shorter lead times and a higher-quality final product with precision-fit components.

Design Advice to Ease Assembly of Your CNC Machined Components

When designing parts that will go into CNC machined assemblies, there are several things you can do to ensure a smooth and efficient assembly process:

- Keep your product’s end use in mind when specifying tolerances, and only use very tight tolerances when absolutely necessary, such as when press-fit assembly is required.

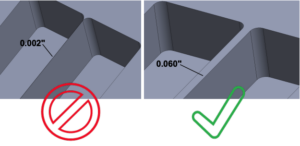

- Incorporate radii in internal pockets where one part slides into another to ensure proper clearance around the mating areas.

- Relax tolerances on the diameters of parts that must fit precisely inside one another to ensure proper clearance around the mating areas. This is especially important for use cases like telescoping tubing.

By keeping these tips and design for manufacturing (DFM) best practices in mind, you help to ensure a smooth manufacturing and assembly process, and reduce the potential for redesign and rework.

Approved Machining: A One-Shop Solution for CNC Machined Assemblies

Partnering with a single precision machining partner can dramatically simplify the complex manufacturing process of CNC machined assemblies, resulting in a higher-quality and more cost-effective product.

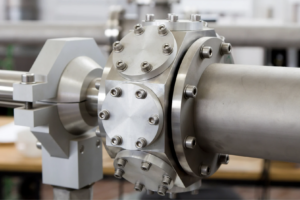

At Approved Machining, we provide comprehensive solutions throughout the entire precision machining and assembly process for products of all sizes. Our dedicated hardware department can easily install PEM hardware, Heli-Coils, rivets, nut and bolt assemblies, and much more. Additionally, our dedicated welding department is outfitted with several booths and staffed with experienced welders who know how to run a quality bead on any type of metal.

With all of our in-house services, combined with our large network of vendors for services like brazing and finishing, Approved Machining can ensure that all of your CNC machined parts will be manufactured with precision, and your finished product will arrive to you assembled, ready to exceed your expectations.

Do you have a CNC machined assembly you’d like to discuss? Request a quote through our secure portal and find out how Approved Machining can be your one-shop solution for precision machining and assembly.